Production processes

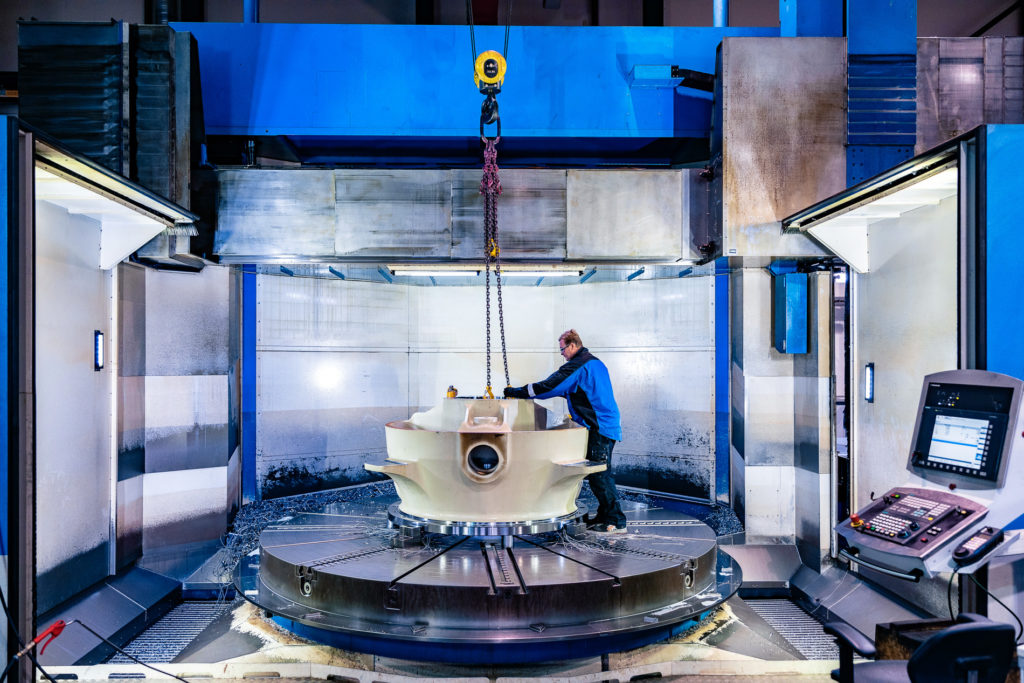

Vertical turning

Power Tech Group’s machinery range for vertical turning is among the most extensive in Finland. All our vertical turning machines are state-of-the-art and equipped with rotating tools, some also with 5-axis turning capabilities.

- Seven vertical turning machines, part of them 5-axis turning machines

- Turning diameter from 500–5000 mm

- Turning height up to 2500 mm

Horizontal turning

We have several CNC turning machines, some of them with 5-axis turning capabilities. The turning diameter ranges from small components up to two meters and the turning length up to six meters.

- Thirteen CNC horizontal turning machines

- Many 5-axis turning machines

- Turning diameter from 10–2000 mm and turning length up to 6000 mm

- Also for small components

- Robotic handling

Milling

We have several CNC machining centers ranging in size up to fourteen meters in length and four meters in height. Most of our machines are equipped with rotating tables and some with pallet changers.

- Eight CNC machining centers, part size from 50x50x50 mm upwards

- Length of the working area up to 14000 mm, height up to 4000 mm

- Rotating tables and pallet changers

- Rotating table load capacity up to 30 tons

Gearing

Gear hobbing and 5-axis milling are used in external and internal gear cutting.

- Five traditional gearing machines

- 5-axis machines for external gears

- Maximum outside/inside diameter of one meter

Welding and plate work

We specialize in complex plate work and welding austenitic stainless, acid-resistant and duplex steel. We also weld structural steel and specialized materials like SMO or dissimilar joints.

Our welding operations follow the certified ISO 3834-2 quality requirements. We have an extensive selection of welding procedure specifications qualified by welding procedure tests for different materials, and all our welders have passed the ISO 9606-1 qualification testing. The welding operations are supervised by an IWE-certified welding coordinator.

One of our two welding workshops specializes in rotationally symmetrical parts (maximum diameter 5 meters, maximum weight 12 tons), the other in long products. Our machine range includes modern MIG/MAG and TIG welding machines, rotating tables for efficient handling as well as regular plate work machines. Our own stock of plates and our flame/plasma cutting facilities allow us to respond quickly to customer needs.

- Specialized in welding complex HST/RST/Duplex structures

- Certified welders, ISO 3834-2 quality requirement compliant, IWE

- Modern MIG/MAG/TIG machinery and a good selection of rotating tables

- Two welding workshops, combined production space of some 2,500 m2

- Rotating table load capacity up to 30 tons

NDT and measuring

Power Tech Group uses third-party resources to perform NDT for quality assurance in welding and machining. The inspectors employ the full range of NDT methods and are always qualified according to customer requirements.

For measuring we use a 3D coordinate measuring machine to verify dimensions as well as geometrical tolerances. The measuring area is 2000 x 3300 x 1500 mm; measurements for larger parts can be obtained using the machine’s own measuring probes or the 3D measuring devices of our partners. Measurement results are recorded in our own digital system.

- CMM measurements (measuring area 2 m x 3.3 m x 1.5 m)

- Non-destructive testing performed by third-party inspectors

- Other measuring and quality assurance services through our partner network

Assembly, surface finishing and testing

Our assembly unit offers flexible and diverse assembly, surface finishing, testing and logistics services.

- Surface finishing: painting, pickling

- Mechanical assembly, and pneumatic, hydraulic and electric installations

- Various testing processes available according to customer specifications

- Load tests, pressure tests, leakage tests (water, air, helium), functionality tests